Checking out the Advantages and Applications of Heat Transfer Systems in Modern Industry

Heat transfer systems play a crucial duty in modern market. They incorporate different mechanisms such as radiation, convection, and transmission, each adding to effective thermal administration. Industries like manufacturing and aerospace advantage significantly from these systems. As advancements proceed, the combination of ingenious materials and modern technologies assures to improve energy performance. This development raises essential inquiries about the future effects for sustainability and functional prices across multiple fields. What exists ahead in this ongoing makeover?

Comprehending Heat Transfer Concepts

Heat transfer concepts are fundamental to the procedure of different commercial systems. These principles incorporate the systems of conduction, convection, and radiation, each playing a crucial role in handling thermal power. Comprehending transmission includes evaluating just how Heat moves via strong materials, while convection refer to Heat transfer in fluids, driven by liquid activity. Radiation, distinct from the various other two, entails energy transfer via electromagnetic waves. The effectiveness of Heat transfer effects system efficiency, energy intake, and overall efficiency. Reliable thermal management is crucial in processes such as cooling, Heat, and heating recovery. By grasping these concepts, markets can maximize their procedures, lower power prices, and boost equipment longevity, consequently contributing to a more effective and lasting commercial landscape.

Secret Kinds of Heat Transfer Equipments

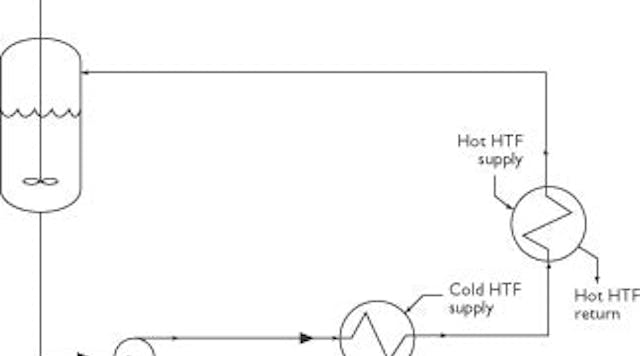

While various industries utilize Heat transfer systems for diverse applications, several key kinds stand apart as a result of their details features and effectiveness. One of the most typical types consist of transmission, radiation, and convection systems. Conduction systems transfer Heat with straight contact in between products, making them reliable in solid-state applications. Convection systems, on the various other hand, use fluid motion to transfer Heat, suitable for heating or cooling down gases and liquids. Radiation systems run without a tool, depending on electromagnetic waves to transfer Heat, suitable for high-temperature atmospheres. Each type offers distinctive functions, enabling industries to tailor their Heat transfer solutions based upon operational needs, power performance, and cost-effectiveness. Comprehending these systems is essential for maximizing efficiency in different industrial setups.

Industrial Applications of Heat Transfer Technologies

The application of Heat transfer technologies in sector plays a necessary function in enhancing power efficiency and maximizing procedures. DVS Heat Transfer Systems. By implementing innovative Heat exchange systems, companies can greatly reduce their ecological influence while enhancing total efficiency. This assimilation not just fosters sustainability yet likewise lines up with modern-day regulatory and customer demands for greener techniques

Energy Performance Improvements

As industries progressively focus on sustainability, energy effectiveness renovations in Heat transfer innovations have actually become crucial for minimizing functional expenses and ecological impact. Improved Heat exchangers, as an example, use innovative materials and styles to optimize thermal efficiency while reducing energy intake. Incorporating variable rate drives in pumping systems allows for better control of fluid circulation, leading to substantial energy savings. The execution of clever sensing units and automation provides real-time tracking, allowing changes that maximize power usage. Additionally, waste Heat recuperation systems record excess thermal power, transforming it into usable power. These improvements not just enhance power efficiency yet likewise add to an extra lasting commercial landscape by lowering greenhouse gas exhausts and sustaining conformity with ecological guidelines.

Refine Optimization Techniques

Process optimization methods are critical in improving the performance and effectiveness of Heat transfer innovations in industrial applications. These techniques involve refining procedures to maximize Heat transfer efficiency while decreasing power consumption and operational costs. Approaches such as computational liquid dynamics (CFD) modeling allow designers to imitate and assess Heat transfer scenarios, recognizing locations for improvement. Additionally, real-time surveillance systems can supply important information on temperature gradients and circulation rates, enabling changes that enhance performance. In addition, applying sophisticated control techniques, such as anticipating analytics, can improve system responsiveness to varying functional demands. By using these optimization techniques, sectors can accomplish greater thermal effectiveness, reduced downtime, and enhanced product high quality, ultimately resulting in boosted competitiveness in the industry.

Ecological Influence Reduction

While industrial Heat transfer modern technologies are vital for functional effectiveness, their application additionally provides possibilities for considerable ecological influence reduction. By enhancing power efficiency, these systems reduce gas consumption, resulting in reduced greenhouse gas discharges. For example, advanced Heat exchangers can recuperate waste Heat, rerouting it to preheat incoming fluids, thus lowering power demands. On top of that, the assimilation of Heat transfer innovations in renewable Check This Out resource systems, such as solar thermal and geothermal applications, supports the shift to lasting techniques. Industries that employ these innovations additionally profit from reduced operational costs and enhanced regulative compliance. On the blog whole, the strategic implementation of Heat transfer systems not just bolsters productivity but likewise promotes a more sustainable industrial landscape, contributing to global environmental goals.

Benefits of Reliable Heat Transfer Equipments

Reliable Heat transfer systems use substantial benefits in modern-day market, mainly with enhanced energy efficiency and cost decrease. By maximizing thermal monitoring, these systems lessen energy waste, resulting in lower operational expenses (DVS Heat Transfer Systems). Businesses can accomplish greater sustainability and enhanced earnings.

Energy Effectiveness Improvements

As sectors increasingly prioritize sustainability and cost-effectiveness, energy effectiveness renovations in Heat transfer systems have emerged as an important emphasis. Boosted performance in these systems leads to reduced power intake, enabling centers to operate more sustainably. By enhancing Heat transfer techniques, markets can lessen waste Heat and accomplish much better thermal management, significantly reducing their ecological influence. Advances in technologies such as Heat exchangers and insulation products add to enhanced efficiency and dependability. Moreover, carrying out energy-efficient Heat transfer services not only sustains compliance with regulatory standards but additionally cultivates a culture of technology within companies. Ultimately, these improvements are essential in straightening industrial operations with international energy preservation objectives, paving the means for a more sustainable future in manufacturing and handling sectors.

Price Reduction Opportunities

By maximizing Heat transfer systems, industries can expose significant price reduction possibilities that enhance their lower line. Effective Heat transfer minimizes energy intake, resulting in reduced utility costs and lessening functional expenses. In addition, boosted system performance lowers the requirement for repair and maintenance, in addition saving expenses with time. Enhanced Heat transfer can also expand devices lifespan, allowing business to delay funding expenditures on replacements. In addition, waste Heat healing systems can transform excess Heat into useful energy, additionally driving down prices. These systems not only improve procedures yet additionally contribute to sustainability efforts, placing firms positively in a progressively eco-conscious market. Overall, the monetary benefits of reliable Heat transfer systems are necessary and significant for affordable benefit.

Innovations in Heat Transfer Solutions

How can modern industry improve its procedures through cutting-edge Heat transfer services? By taking on innovative products and modern technologies, sectors can greatly improve thermal efficiency and performance. Innovations such as nanofluids, which boost Heat transfer capacities past standard liquids, and phase modification materials that store and launch thermal energy, are acquiring traction. Additionally, the combination of wise sensors and IoT devices permits for real-time surveillance and optimization of Heat transfer procedures, reducing waste and boosting system responsiveness. In addition, additive production techniques make it possible for the production of even more complex Heat exchangers that take full advantage of surface location while lessening material use. Jointly, these advancements drive operational performance and produce affordable advantages in different industries, consisting of power, aerospace, and manufacturing.

The Duty of Heat Transfer in Sustainability Initiatives

While the promote sustainability remains to improve sectors, the function of Heat transfer technologies becomes significantly vital in attaining environmental goals. Reliable Heat transfer systems help with power effectiveness by maximizing thermal administration in numerous processes, significantly reducing energy intake and greenhouse gas discharges. Progressed Heat exchangers are utilized in commercial applications to reclaim waste Heat, therefore minimizing energy waste. Furthermore, advancements such as stage adjustment products enhance thermal storage, adding to renewable energy integration. The adoption of sustainable fluids in Heat transfer systems can minimize environmental effect. By focusing on efficient Heat transfer, markets not only enhance operational efficiency however likewise straighten with international sustainability efforts, promoting a cleaner, see this site a lot more sustainable future.

Often Asked Concerns

Exactly How Do Heat Transfer Equipments Impact Power Prices in Manufacturing?

Heat transfer systems markedly influence energy costs in manufacturing by improving performance, lowering waste, and enhancing thermal administration. These renovations bring about lower functional costs, ultimately profiting overall productivity and earnings in industrial procedures.

What Maintenance Is Needed for Heat Transfer Systems?

Upkeep for Heat transfer systems consists of regular assessments, cleansing of components, examining liquid levels and conditions, changing used components, and ensuring proper insulation. These activities boost efficiency, expand lifespan, and stop pricey malfunctions in operation.

Exist Safety And Security Worry About Heat Transfer Equipments?

Security worry about Heat transfer systems include prospective leaks, stress accumulation, and thermal threats. Proper design, routine upkeep, and adherence to safety and security procedures are vital to minimize these risks and ensure risk-free procedure in industrial atmospheres.

Exactly How Can I Select the Right Heat Transfer System for My Organization?

Choosing the right Heat transfer system entails evaluating elements such as performance, application demands, budget constraints, and security criteria. A detailed analysis of these aspects will aid assure ideal performance and reliability in company operations.

What Are Usual Failings in Heat Transfer Equipments and Their Causes?

Recognizing transmission includes assessing just how Heat relocates through strong materials, while convection pertains to Heat transfer in fluids, driven by fluid activity. By optimizing Heat transfer techniques, sectors can reduce waste Heat and attain far better thermal monitoring, substantially reducing their environmental effect. Waste Heat healing systems can change excess Heat into usable power, better driving down expenses. Advanced Heat exchangers are utilized in industrial applications to recover waste Heat, thus reducing energy waste. Common failures in Heat transfer systems include leaks, deterioration, and ineffective Heat exchange.